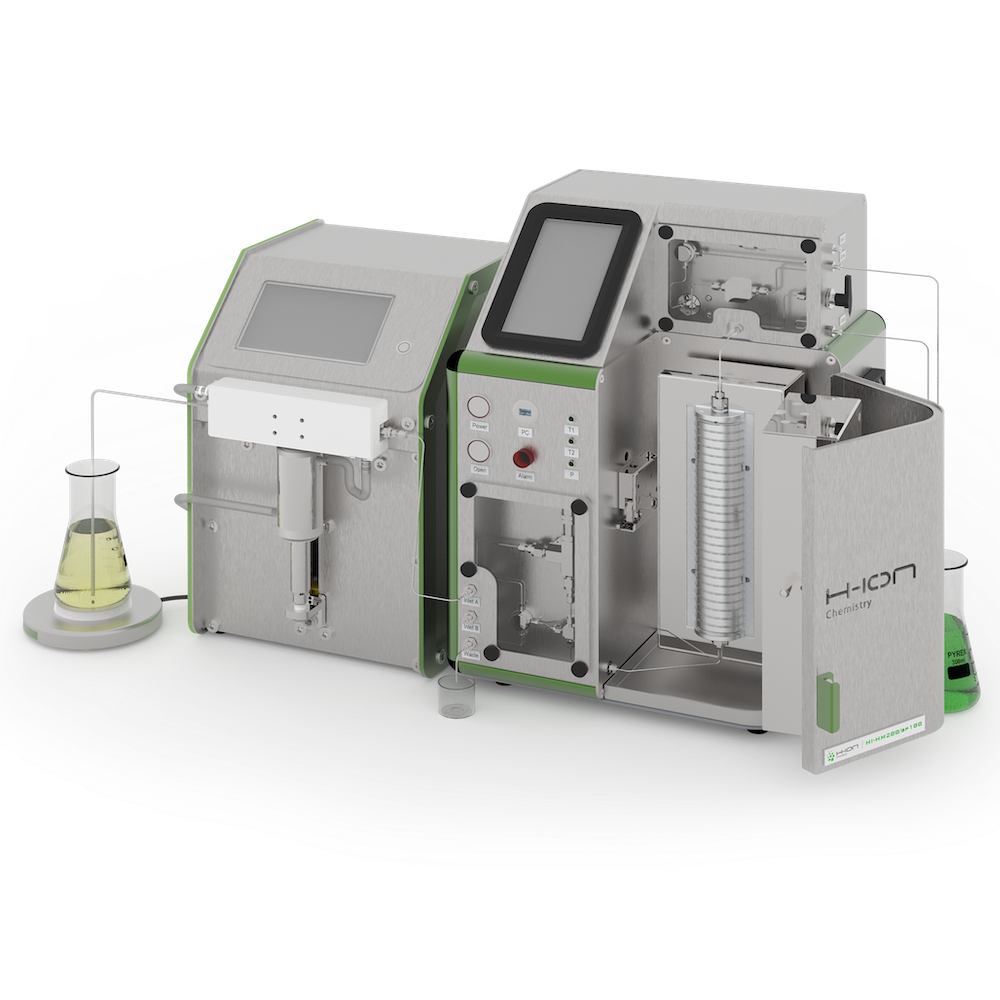

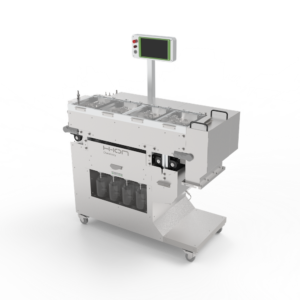

Description

We offer a modular designed continuous flow reactor system, which allows fast and efficient experiments in field of flow chemistry. This flow reactor system includes a liquid-liquid or gas-liquid mixing zone, oven with two heating zones and optional back pressure regulator and quench inlet. The oven is compatible with pack bed columns and coiled loops. Our flow reactor system offers working pressure up to 200 bar and temperature up to 350 °C. Process development, optimizing of reaction conditions, catalyst screening can be performed with it. According to the construction and the applied materials provide the safety operation and long lifetime. Safety parts of the reactors ensure the safe work on high temperature and pressure. Thanks to its modular design the flow reactor system, besides, easy handling, and simply integrate to the laboratories.